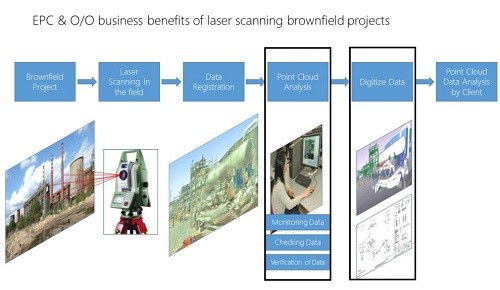

4 Business Benefits of Laser Scanning Brownfield Projects for EPC’s and Owner Operators

4 Business Benefits of Laser Scanning Brownfield Projects for EPC’s and Owner Operators

Laser scanning is a highly accessible tool that enables engineers and designers to think, design and evaluate the brownfield facility that addresses unique challenges after capturing data. Laser scanning devices essentially are non-contact devices. Laser scan data produces “point cloud” that consists of millions of points and it’s extremely accurate in providing information to the engineers and designers.

We know that digitizing brownfield assets is significantly important and we also discussed the value propositions related to it. Based on the 4 value propositions, now that precise and “As is” data is instantly available, it’s important to leverage the 3d laser scanning data which will be of value for designers/ engineers working on CAPEX and OPEX projects at engineering, procurement and construction (EPC’s) firms and owner operators (O/O’s). 3D laser scanning services plays an important role in brownfield projects.

Laser scan data can be used for:

- 3D Modeling and As-built data

- Monitoring data

- Checking data

- Verification of data

3D Modeling & As-built

Precise and “As is” data is available. Laser scan data provides the designers with valuable information such as size of the pipe, length of the pipe, structural cross section information from the data. Using this information, the designers can utilize their engineering design application skills in 3d modeling. The designers need not model the entire facility again. Laser data itself can be used to for clash checks with modeled objects and referenced objects. Laser data can be effectively used referencing the views on orthographic drawings. Value is the as-built data from laser scanning as it saves hundreds of hours of modeling time.

Monitoring Data

A facility can be laser scanned multiple times over a period of time. Laser scan data can be used to monitor equipment, vessels, structures, hulls, tanks etc. in the facility to analyze deformations. This allows the engineers to take corrective actions related to maintenance and operations aspects in the facility.

Checking

Modular construction is a good example in this case. Data needs to be checked and verified before the physical assets are moved to the facility. The components in the module are manufactured at the shop facility and later they are transported to the site. Before the modules are transported, it is important to check if the modules fit correctly or else it will result in huge financial losses and severely hamper project schedules.

Verification

The components/equipment’s manufactured at the facility is designed using 3d modeling applications. However, laser scanned components and equipment’s can used for verification of the design. This helps the designers to quickly address any deviations in the design.

Conclusion

At Bursys Technology Services for brownfield projects, we offer value solutions/services that will value add to your detailed design and generate deliverable data for owner operators, EPC’s and their contractors.

Value for EPC’s and Contractors

- Review laser scanning data from Leica, LFM, Faro, Z+F and other providers.

- 3D modeling, clash checking using engineering design applications.

- General arrangement, detailed, assembly, pipe isometric drawings deliverables.

- Data conversion services for laser scan data and 3D model data generated using laser scans.

Value for Owner Operators and Suppliers/Contractors

- Field services for cost and lifecycle management across supply chain for vendors and customers.

- Ability to access data on an internet webpage which can be valuable for inspection, maintenance and training purposes.